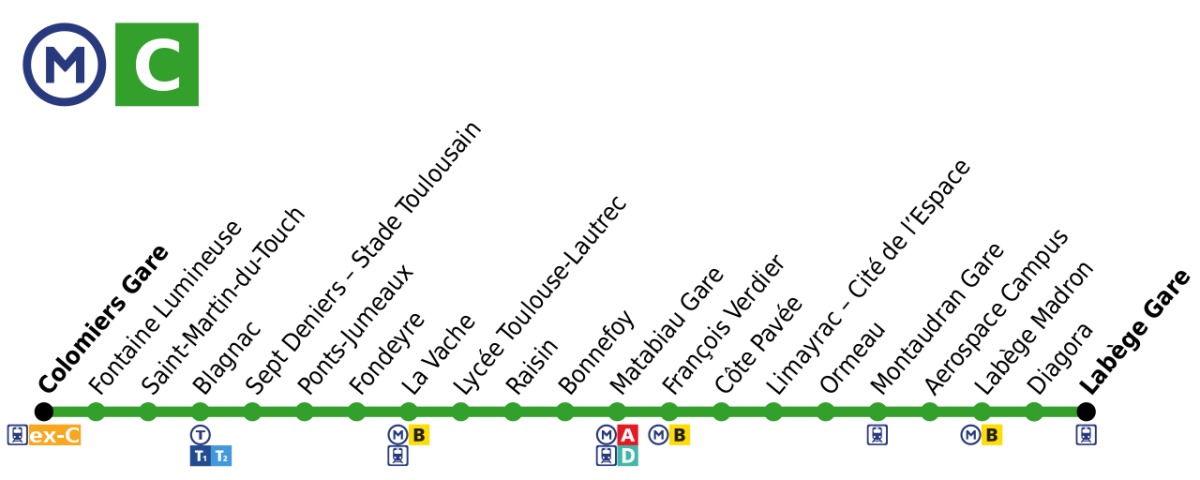

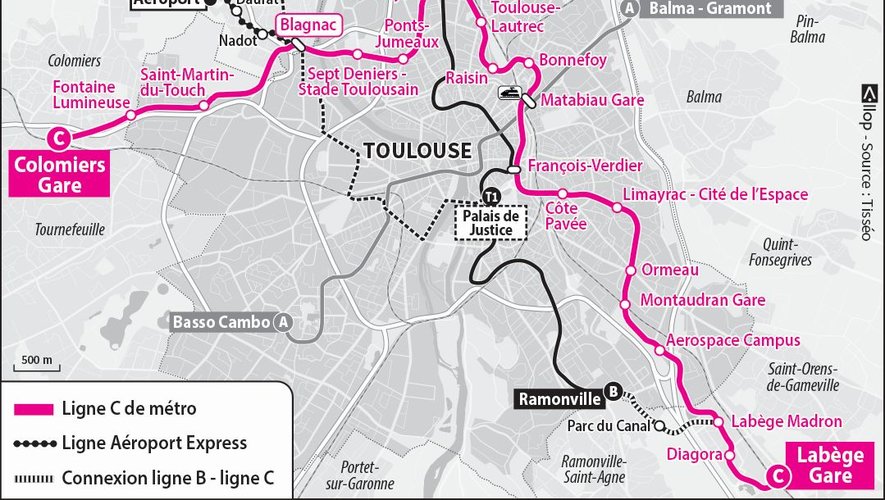

Toulose Metro C will be the third metropolitan line serving the French city of Toulouse.

The entire project, commissioned by the Tisséo Consortium has an extension of more than 27 km, will connect the city of Toulouse from Colomiers to Labège and involves 21 stops and 5 station to reach outer-city destinations.

The project stems from the need to respond to environmental transition’s objects and has the aim to have people move with public transportation instead of private cars (daily estimated flow of 200.000 people).

The Line C extension will allow to develop new residential area and enlarge Toulouse urban area. This extension will allow to connect to each other more Toulouse’s areas.

With this extension, it will also be possible to have a better connection between the Matabiau’s station but also with the Toulouse-Blagnac Airport.

The construction’s team will use a tunnel boring machine for the tunnel excavation and the placement of fibre-reinforced concrete segments, which, according to the consortium, will use less steel across 95% of the project. A new plant will be built in the Toulouse area, for the manufacture of these concrete segments.

The consortium says it plans to recover over 80% of the excavated material. It has also given undertakings to reduce the project’s carbon footprint through the use of primarily renewable energy, clean vehicles, and eco-designed, low-consumption installations.

Furthermore, the 80%of the line extension will be developed underground and due to this, the impact of the excavation’s operations has an high importance in the project. Here STM’s expertise will bring its contribution by supplying several belt conveyor systems for the handling of the excavation’s materials.

Work is expected to start on the project in the 2023 spring, with construction completion slated for the summer of 2027, followed by up to a year of equipment installation works.

The use of belt conveyor systems, as enlighted in the Milan’s Blu Metro Project, allows to redure heavy vehicles’s passage in the city centres and to increase the material handling of the excavation’s operations.

With this object, alongside STM’s experience gained during the last years, such as the supply for the Grand Paris Express Metro and the Montreal’s Metro, has led the Client to pick STM and its belt conveying system for the material’s handling, even with specific belt called ‘Borflex’ which will allow to work in reduced spaces.